Integrated circuits of the University of Wuppertal open up the Terahertz frequency range (100GHz-10THz), one of the last "dark" areas of the electromagnetig spectrum.

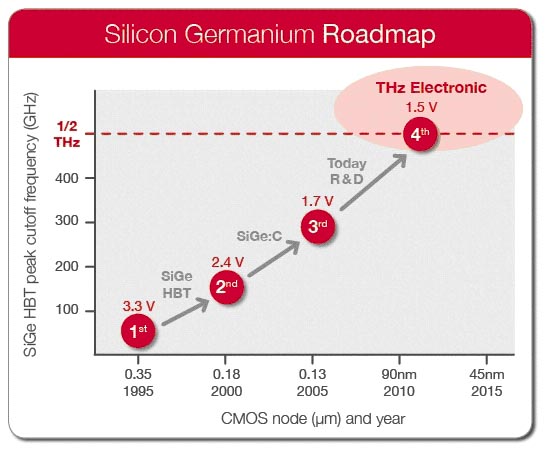

The commercial use of the terahertz frequency range will require cost-effective and highly integrated electronic systems in the future. Under the direction of Prof. Dr. Ullrich Pfeiffer, research on silicon-integrated high-frequency circuits is being conducted at the Institute for High Frequency & Communication Technology. In close cooperation with industry, silicon process technologies are being developed that are expected to achieve transistors with cutoff frequencies of half a terahertz in a few years (Figure 1). The cut-off frequencies of silicon hetero-junction bipolar transistors (HBTs) have been gradually improved in the past. Current research and development (R&D) is concerned with the 4th generation of silicon transistors which are expected to reach cut-off frequencies of half a terahertz in a few years.

As a partner in the 7th European Research Framework Programme (DOTFIVE), the University of Wuppertal develops circuits for modern information technology: high-speed data transmission, radar applications for the automotive sector, as well as mmWave/THz imaging and sensor technology (Figure 2).

Silicon transistors are available on one chip in an almost unlimited number and high yield. This enables high-resolution focal plane arrays with sophisticated signal processing. Current prototypes make use of the interaction of terahertz radiation with a two-dimensional electron plasma and thus enable the detection of terahertz radiation up to 650 GHz (Figure 3).

Terahertz cameras can be used for security checks at airports: Terahertz waves look through suitcase walls and clothing and detect hidden weapons and explosives. In medicine, researchers hope to replace numerous X-ray examinations with harmless terahertz waves. In industry, compact and fast terahertz cameras open up perspectives for radar applications in the automotive sector or non-destructive quality inspections on the assembly line, since they can also look into many materials.

If a letter is X-rayed, an interesting picture is revealed to the observer: text, metal parts or ID cards are clearly visible. At higher frequencies a better resolution is achieved, but the strength of the absorption also allows conclusions to be drawn about existing materials.